INDUSTRIAL GREASES

Grease has a much higher non-flowability compared to other lubricants. The calcium, sodium or lithium soap gel in greases is emulsified with mineral and synthetic oils.

COLDEX

Calcium Sulfonate Complex Grease

Coldex is a product that has the ability to carry much more load by going beyond the standards. At the same time, it offers long-term working performance thanks to its ability to operate in wide temperature ranges.

MADE IN

TÜRKİYE

All Orders

Free Shipment

On-site Problem

Detection

Technical

Consulting

Frequently Asked Questions About Greases

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Grease has a much higher non-flowability compared to other lubricants. Original greases contain calcium, sodium or lithium soap gel, emulsified with mineral and synthetic oils.

What is grease? The most accurate answer to the question is that it is a type of oil in which a thickening agent and a fluid oil vary between solid and semi-fluid structure. The thickening parts of greases, which are usually a synthetic or petroleum-based mineral lubricant, are called metallic soap.

Grease oil is widely used in different areas of the industry to prevent wear, especially in mechanical parts, and to keep them functioning comfortably for a long time. Compared to other lubricants, they have many advantages in the areas where they are used. The most important of these is that they do not flow and drip after application due to their dense consistency. This feature of greases is an important advantage as it facilitates their separation by flotation processes.

Since it is a necessity to increase its viscosity, it is mixed with soap. In this way, the heat resistance of grease produced using different types of soap can also be determined. Grease oil is actively used in high pressure environments and in important machine parts and bearing housings of these machines where liquid oils are not sufficient.

Grease Oil Usage Areas

The use of grease oil dates back to ancient times. This material, which significantly extends the life of machines, also contributes to their proper functioning. For this reason, it is actively used in many areas of industry.

This oil, which significantly streamlines the operating systems of the machines, ensures that they are protected from damage that may occur during friction. Thanks to its damage prevention feature, grease helps machines to work longer and reduce operating costs.

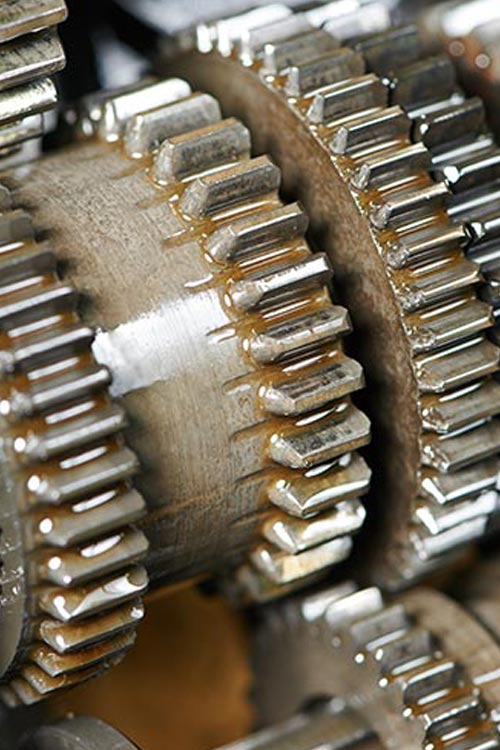

- It is widely used in gears and other parts of machines.

- In the engines of vehicles and freight transport vehicles,

- Commonly in tractors and motorcycles,

- It is widely preferred as an indispensable material in the industrial sector.

- In all mechanical components,

- Extremely high temperatures and low temperatures,

- In areas where heavy loads are used,

- In many sectors in the maritime field,

- In the cement industry, in bearings and kiln bearings where dust is dense and operating at high temperatures,

- All bearings and housings in contact with seawater,

- In moving belt conveyor beds working with difficult conditions,

- In the iron and steel industry,

- In all precision and optical bearings,

- In vibrating mechanisms where plastic and steel components work together,

- Lubrication of turrets,

- In roller bearings,

- Equipment in sterile rooms,

- In all robotic manufactured devices,

- All machines in contact with water or salt water,

- For gear wheels operating at high speeds thanks to their high retention properties,

- Grease can be used safely on special gear shafts.

When grease is used in vehicles, it helps to clean and keep the mechanical parts clean. At the same time, it significantly extends service maintenance times, allowing parts to work healthier and longer. In addition, it significantly reduces oil consumption and ensures more stable operation of vehicles. In areas where grease is used, wear that may occur as a result of adverse conditions is prevented and parts are made more compatible with each other.

Grease Oil Properties

Grease has a wide range of uses. The most preferred ones are high temperature greases that can be used in air, sea and land. These types of greases exhibit extra resistance to water and extremely high temperatures, ensuring the correct operation of the machines in the environments in which they are used, reducing maintenance times and extending their life.

The grease provides excellent protection for boundary protection parts. There are options that can exhibit superior performance from temperatures below 0 to 250 degrees Celsius. Greases that can be highly resistant to moisture and rust provide extra protection against corrosion. By lubricating without losing its properties even in long-term use, it helps to noticeably extend the lubrication intervals.

Grease Oil Types

White Grease Oil; It is widely used in the pharmaceutical industry and food industry. It is an ideal option for high temperature applications and perfectly adapts to harsh conditions. In the automotive industry, it serves the purpose of lubricating mechanical parts.

Bearing Grease Oil; It is preferred for bearings with operating temperatures up to a maximum of 140 degrees. It is actively preferred in heavy load transportation and central lubrication systems. Bearing greases prevent parts from freezing by exhibiting superior lubrication performance even in cold weather.

Silicone Grease Oil; Silicone grease oils are high quality lubricant materials. Due to their structure, they harden and do not stick to the area where they are used. Suitable for lubrication of mechanisms in all moving parts. They can be used long-term without dripping.

They prevent the formation of dirt and moisture in the area where they are used as grease. They are versatile lubricants for nuts, screws, bolts, etc. It also provides protection against corrosion in shafts, valves, machine parts, gaskets, seals used as assembly aids.

Liquid Grease Oil; It is preferred because it is a high performance and multi-purpose grease. Its non-sticky formula significantly prevents water penetration, corrosion and contamination. Excellent results can be obtained when using grease oil in metal joints. They are specially designed to facilitate lubrication under high pressure loads.

Nsf Approved Grease Oil

The lubricants of choice in machinery used for the production and processing of food must be non-toxic. At the same time, they must meet the rules set according to the food compounds being used in food production facilities.

NSF Certification assures food inspectors and consumers that the cleaning chemical used in production is suitable for food safety. Industrial grease used in the production or packaging of food is called grease.

The content of lubricants used in the entire food industry is very important for human health. For this reason, they must be tasteless, odorless and in compliance with food regulations and international standards.

Another feature is that they reduce friction and wear. They are resistant to high temperatures, have sealing properties and can prevent corrosion. Choosing the right lubricant is very important for reliability and increasing the life of the equipment. For this reason, you can get help from the technical team in your Corfin brand Nsf approved grease selection.

High quality Corfin Nsf approved grease minimizes operating and maintenance costs and pays back the investment in the long term. All of the lubricants have proven their value and fully serve today’s requirements. You can easily decide on the most suitable product for you by examining the tried and tested greases on the page.

Food grade grease is directly related to human health and has a responsibility to protect it. These lubricants, which are also frequently used in the pharmaceutical industry, must have passed all necessary tests and have received approval certificates. Corfin offers all Nsf approved greases for your use after successfully passing the necessary tests.

Grease oil prices may vary according to usage areas and sizes. For this reason, it is very important to understand where and how it should be used correctly before making the purchase. Corfin’s expert team and experienced field staff provide you with the support you need for grease.

NSF Approved Grease Oil Areas of Use

- In all facilities that carry out food production and packaging processes,

- Lubrication of yellow material bearings of Rotary Presses used in the production of tablet drugs,

- Wet and vibrating bearings of machines used in the food industry,

- On conveyor beds with moving belts working under difficult conditions,

- In all marine vessels, bearings and plain bearings,

- All bearings and bearings in contact with salt water and water,

- Nfs approved grease is used in all high temperature bearings and bearings.