SKU 310201

Category Greases

Calcium Sulfonate Complex Grease

COLDEX

Calcium Sulfonate Complex Grease Advantages

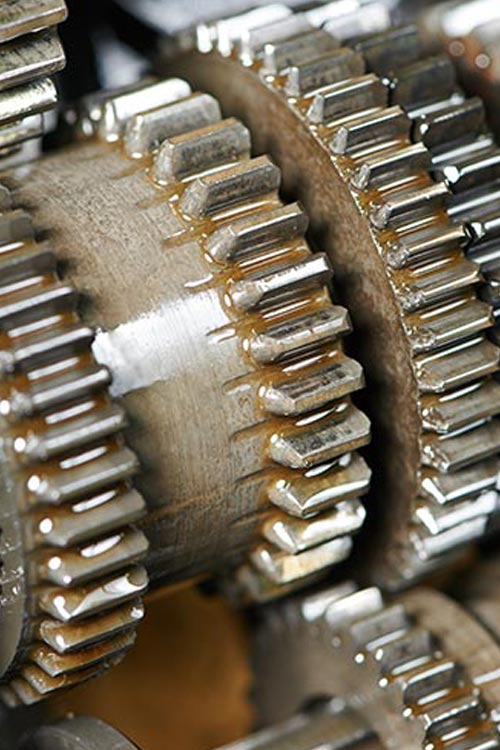

Calcium sulfonate greases are commonly used in automotive, agriculture, construction, mining, paper production, iron and steel mills and the food industry. Specific automotive applications include chassis, ball joints, universal joints and wheel bearings. Industrial applications include continuous casters, conveyors, ball mills, crushers, offshore and underwater applications.

Calcium sulfonate greases are also used in motorized steam valves to control high pressure steam. These steam valves are typically found in nuclear power plants and thermal manufacturing stations. It is also known that the calcite particles found in calcium sulfonate greases make them a good choice for high temperature applications.

Calcium sulfonate greases are generally beneficial in rust-inhibiting performance and oxidation stability is considered good or excellent. Rust inhibitors are surfactants that neutralize acids on the metal surface. They can also form an oily surface or barrier to stop rust on the surface.

Excellent durability under extreme loads.

Provides superior protection against rust and corrosion.

The cost is much lower because the lubrication period is long-lasting.

Calcium Sulfonate Complex Grease Features

- -20 / 185 °C Wide operating temperature range.

- Sulfonate grease is resistant to water and chemicals.

- Resistant to oxidation and long-lasting.

- Its pumpability is very high.

- It has very good retention properties.

Calcium Sulfonate Complex Grease Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

YOU MAY

ALSO

INTEREST

PRODUCTS

Calcium Sulfonate Complex Grease Tech Data

| ANALİZLER | STANDART | BİRİM | SONUÇ |

|---|---|---|---|

| Color | Blue - Green | ||

| Appearance | Homogeneous | ||

| Thickener | Calcium Sulfonate Complex | ||

| Base Oil | Paraffinic Mineral | ||

| Base Oil Viscosity (cst) at 40 °C | ASTM D445 | cSt | 460 |

| Temperature Range | °C | -20 / 185 | |

| NLGI Class | 1,5 / 2 | ||

| Dropping Point | ASTM D2265 | °C | > 300 |

| Seperation from Oil (% weight) 30 hours / 100 °C | ASTM D1742 | %wt | %2,5 |

| Seperation from Oil (% weight) 7 days / 40 °C | IP 121 | %wt | 0,15 |

| Four Ball Test 1 hour/75 °C - 40kg (392 N) | ASTM D2266 | mm | <0,40 |

| Four-Ball EP Test 10 sec. / 1770 rpm Speed | ASTM D2596 | kg | > 400 |

| Water Washout | ASTM D1264 | Max. %7,5 | |

| Water Spray ( % weight) 38,5 °C, 5dk, Max | ASTM D4049 | %wt | %15 |

| Rust Test | ASTM D1743 | Pass |

Calcium Sulfonate Complex Grease Frequently Asked Questions

Contact Form

MADE IN

TÜRKİYE

FOR ALL ORDERS

FREE SHIPMENT

ON-SITE PROBLEM

DETECTION

TECHNICAL

CONSULTING

WHAT IS CALCIUM SULFONATE GREASE?

Not new to the grease market, calcium sulfonate grease has been in use for almost 50 years. This particular type of grease has natural extreme pressure resistance properties that set it distinctive from others. These properties, combined with the fact that it can be formulated for use in food grade applications, make it an attractive alternative to other greases.

CALCIUM SULFONATE COMPLEX GREASE TYPES

There are numerous grease thickeners available in sulfonate grease production, each with their own strengths and weaknesses. Briefly, typical lithium-based greases are made from a fatty acid, usually 12-hydroxystearic acid, and a lithium base to produce a simple soap that acts as a grease thickener. Components are then added that will allow the EP and equipment to operate at their peak performance.

To make a lithium-based complex sulfonate grease, part of the fatty acid is replaced by another acid that makes the complex soap. This type of mixed soap structure has special properties that allow the grease to be heated to a higher temperature without losing its structure or letting the oil separated from the thickener.

This maximum temperature is called the dropping point. The dropping point is critical because it is the temperature point at which the grease passes from a semi-solid to a liquid state (the oil separates from the thickener). Calcium sulfonate grease has a higher dropping point, making it attractive for some high temperature applications.

Calcium sulfonate grease is obtained by converting a liquid detergent containing amorphous calcium carbonate into a grease containing calcite particles. Due to the lubricating properties of calcite particles, performance additives that contain sulfur, phosphorus or zinc may not be needed. Therefore, some calcium sulfonate-based greases are attractive for the food industry.

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.

SKU 310201

Category Greases

Calcium Sulfonate Complex Grease

COLDEX

THICKENER

Calcium Sulfonate Complex

BASE OIL

Paraffinic Mineral

NLGI

1,5, 2

20 kg, 200 kg

1-3 Weeks

-

MADE IN

TÜRKİYE

-

FOR ALL ORDERS

FREE SHIPMENT

-

ON-SITE PROBLEM

DETECTION

-

TECHNICAL

CONSULTING

Calcium Sulfonate Complex Grease Advantages

Calcium sulfonate greases are commonly used in automotive, agriculture, construction, mining, paper production, iron and steel mills and the food industry. Specific automotive applications include chassis, ball joints, universal joints and wheel bearings. Industrial applications include continuous casters, conveyors, ball mills, crushers, offshore and underwater applications.

Calcium sulfonate greases are also used in motorized steam valves to control high pressure steam. These steam valves are typically found in nuclear power plants and thermal manufacturing stations. It is also known that the calcite particles found in calcium sulfonate greases make them a good choice for high temperature applications.

Calcium sulfonate greases are generally beneficial in rust-inhibiting performance and oxidation stability is considered good or excellent. Rust inhibitors are surfactants that neutralize acids on the metal surface. They can also form an oily surface or barrier to stop rust on the surface.

Excellent durability under extreme loads.

Provides superior protection against rust and corrosion.

The cost is much lower because the lubrication period is long-lasting.

Calcium Sulfonate Complex Grease Features

- -20 / 185 °C Wide operating temperature range.

- Sulfonate grease is resistant to water and chemicals.

- Resistant to oxidation and long-lasting.

- Its pumpability is very high.

- It has very good retention properties.

Calcium Sulfonate Complex Grease Usage Areas

Which Industries

Should Prefer?

You can contact us for any questions you may have

IN THESE PRODUCTS

YOU MAY BE INTERESTED

Calcium Sulfonate Complex Grease Tech Data

| ANALİZLER | STANDART | BİRİM | SONUÇ |

|---|---|---|---|

| Color | Blue - Green | ||

| Appearance | Homogeneous | ||

| Thickener | Calcium Sulfonate Complex | ||

| Base Oil | Paraffinic Mineral | ||

| Base Oil Viscosity (cst) at 40 °C | ASTM D445 | cSt | 460 |

| Temperature Range | °C | -20 / 185 | |

| NLGI Class | 1,5 / 2 | ||

| Dropping Point | ASTM D2265 | °C | > 300 |

| Seperation from Oil (% weight) 30 hours / 100 °C | ASTM D1742 | %wt | %2,5 |

| Seperation from Oil (% weight) 7 days / 40 °C | IP 121 | %wt | 0,15 |

| Four Ball Test 1 hour/75 °C - 40kg (392 N) | ASTM D2266 | mm | <0,40 |

| Four-Ball EP Test 10 sec. / 1770 rpm Speed | ASTM D2596 | kg | > 400 |

| Water Washout | ASTM D1264 | Max. %7,5 | |

| Water Spray ( % weight) 38,5 °C, 5dk, Max | ASTM D4049 | %wt | %15 |

| Rust Test | ASTM D1743 | Pass |

Calcium Sulfonate Complex Grease Frequently Asked Questions

Contact Form

WHAT IS CALCIUM SULFONATE GREASE?

Not new to the grease market, calcium sulfonate grease has been in use for almost 50 years. This particular type of grease has natural extreme pressure resistance properties that set it distinctive from others. These properties, combined with the fact that it can be formulated for use in food grade applications, make it an attractive alternative to other greases.

CALCIUM SULFONATE COMPLEX GREASE TYPES

There are numerous grease thickeners available in sulfonate grease production, each with their own strengths and weaknesses. Briefly, typical lithium-based greases are made from a fatty acid, usually 12-hydroxystearic acid, and a lithium base to produce a simple soap that acts as a grease thickener. Components are then added that will allow the EP and equipment to operate at their peak performance.

To make a lithium-based complex sulfonate grease, part of the fatty acid is replaced by another acid that makes the complex soap. This type of mixed soap structure has special properties that allow the grease to be heated to a higher temperature without losing its structure or letting the oil separated from the thickener.

This maximum temperature is called the dropping point. The dropping point is critical because it is the temperature point at which the grease passes from a semi-solid to a liquid state (the oil separates from the thickener). Calcium sulfonate grease has a higher dropping point, making it attractive for some high temperature applications.

Calcium sulfonate grease is obtained by converting a liquid detergent containing amorphous calcium carbonate into a grease containing calcite particles. Due to the lubricating properties of calcite particles, performance additives that contain sulfur, phosphorus or zinc may not be needed. Therefore, some calcium sulfonate-based greases are attractive for the food industry.

The information contained on this page is based on our current experience and is intended to provide information on appropriate use or application based on technical experience. It does not constitute a warranty or guarantee for the product. It is recommended that you contact us for your specific applications and for more comprehensive information. Akoni Kimya reserves the right to change all of the information on this page without notice.